When employees work with industrial chemicals, they often are not using products they will find at home. However, ammonium hydroxide is one exception. Used in everything from household cleaners to industrial processes, it is toxic in all solutions.

Ammonium hydroxide is a colorless liquid with a strong odor and bad taste. It is used as a food additive, for industrial cleaning and in a variety of industrial settings including:

- Public water treatment systems

- Pharmaceutical manufacturing

- Metal extraction

Although in weakened solutions it can be used as a food additive and in household cleaners, employees must treat ammonium hydroxide like any other hazardous chemical. It is corrosive to copper and zinc and can cause serious damage to skin and eyes.

Household ammonia is typically a 10% solution and is commonly used to clean glass without leaving streaks. It is not effective as a disinfectant. Industrial ammonium hydroxide can be found in solutions of up to 30%. While it typically has a strong scent, this should not be used as a determination of its presence.

Safely Using Ammonium Hydroxide

Ammonium hydroxide should always be stored in well-ventilated areas. Glass, plastic or rubber containers can be used, but they must be stoppered and only partially filled. Never store ammonium hydroxide at any solution with or near food or food-type products. It should also never be stored in areas with sewers.

Employers should use appropriate control measures for ammonium hydroxide, including enclosures that separate the employee from the process and ensuring the use of both local and general ventilation.

Some employers may choose to use stricter PELs provided by organizations like the National Institute for Occupational Safety and Health (NIOSH), which set an 8-hour TWA of 25 ppm. NIOSH also set a short-term suggested TWA of 35 ppm. Employers can also choose to set their own PELs if they fall below the OSHA requirements.

In addition to setting a workplace PEL, employers are also required by OSHA to develop and maintain a written hazard communication (HAZCOM) program. Employers must:

- Maintain copies of SDSs that are accessible to employees

- Train over any hazardous chemicals that employees may be exposed to

- Train employees to detect and respond to a spill or other accidental release

- Provide training over exposure protection, including personal protective equipment (PPE)

Looking for more online safety training content?

VIEW THE 800+ COURSES AVAILABLE!

Ammonium Hydroxide and Hazard Controls

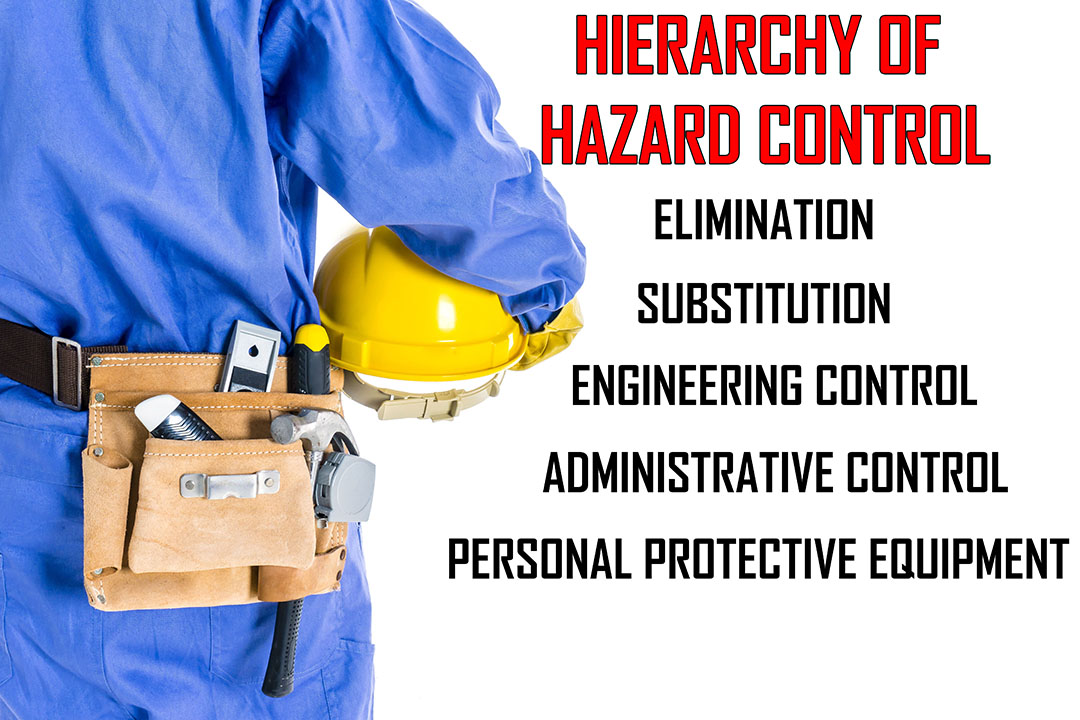

Employers should also cover the hierarchy of hazard controls, ensuring all employees are familiar with effective forms of protection and how to use them.

The most effective hazard controls are elimination and substitution. Replacing ammonium hydroxide with a safer alternative provides the best employee protection. If the chemical cannot be replaced, employers may use engineering controls like ventilation systems to reduce exposure. In addition to engineering controls, employers can use administrative controls to reduce employee exposure to a safe level. These can include work schedules that rotate employees and trainings.

If other hazard controls are unable to reduce employee exposure to safe levels, they may be required to use PPE. In general, employers must provide PPE to employees at no cost. When working with ammonium hydroxide, PPE will generally include:

- Safety goggles

- Long sleeves and pants

- Gloves

For employees who are trained to clean spills or are working with high concentrations of ammonium hydroxide, additional PPE will likely be required. Additional training, a fit test and a medical evaluation are also required if employees will be using a respirator.

What to Do in Case of Exposure

Even if an employee is only exposed to a small amount of ammonium hydroxide, it can still be hazardous to their health. If exposed, employees may experience:

- Eye irritation, including redness and pain

- Contact burns, including blisters and burns

- Difficulty breathing

All these symptoms should be treated promptly and should be evaluated by a medical professional as soon as possible. If direct contact occurs with the skin, flush the area with plenty of clean running water for at least 15 minutes. Remove any contaminated clothing that isn’t stuck to the skin.

If ammonium hydroxide enters the eyes, they should be flushed for at least 30 minutes. Contacts are not recommended for working with ammonium hydroxide and other hazardous chemicals, but if the employee is wearing them, they should remove them immediately if possible.

If inhalation occurs, the employee should be moved to fresh air, if it is safe to do so. Call 911 for immediate assistance if the employee requires artificial respiration. While rare, ingestion can occur if employees using the chemical don’t wash their hands before eating or drinking.

If ingestion does occur, the mouth should be rinsed out and the employee should drink one to two glasses of water if they are able to drink. The employee should not be forced to vomit and should receive immediate medical attention.

Conclusion

Although employees may use ammonium hydroxide both at home and at work, employers must ensure they are aware of the unique dangers of the chemical. Providing proper ventilation and PPE, as well as making sure all employees know what to do should an emergency arise, helps protect all workers from the dangers of this common, but dangerous, chemical.