Many employees in many different industries work with hazardous chemicals. The Occupational Safety and Health Administration (OSHA) has an Occupational Chemical Database currently listing more than 850 hazardous chemicals used in U.S. workplaces. Many of these chemicals can cause injury or death if workers don’t take the right precautions.

Your workplace needs to have a hazard communication (HAZCOM) plan in place to help workers understand the chemical hazards they could be exposed to, how to obtain information on those chemicals and what to do if a spill or accident occurs in their work area.

HAZCOM Plan

To help keep workers safe, OSHA requires your workplace to have a HAZCOM plan addressing your workplace’s chemical hazards. HAZCOM plans give workers the knowledge, training and equipment to help them work safely around the chemicals in their workplace. Your facility’s HAZCOM plan must include:

- All chemicals used in your workplace and their protective measures

- Each chemical’s label and warning information

- Training requirements for each chemical

- Where each chemical’s safety data sheet (SDS) can be found and reviewed

Globally Harmonized System

OSHA follows the procedures for chemical labeling set by the Globally Harmonized System (GHS) for most chemicals used in U.S. workplaces. Almost all U.S. chemical manufacturers, importers, distributors and employers use the GHS to prepare their HAZCOM programs.

Looking for more online training content?

GHS Label Information

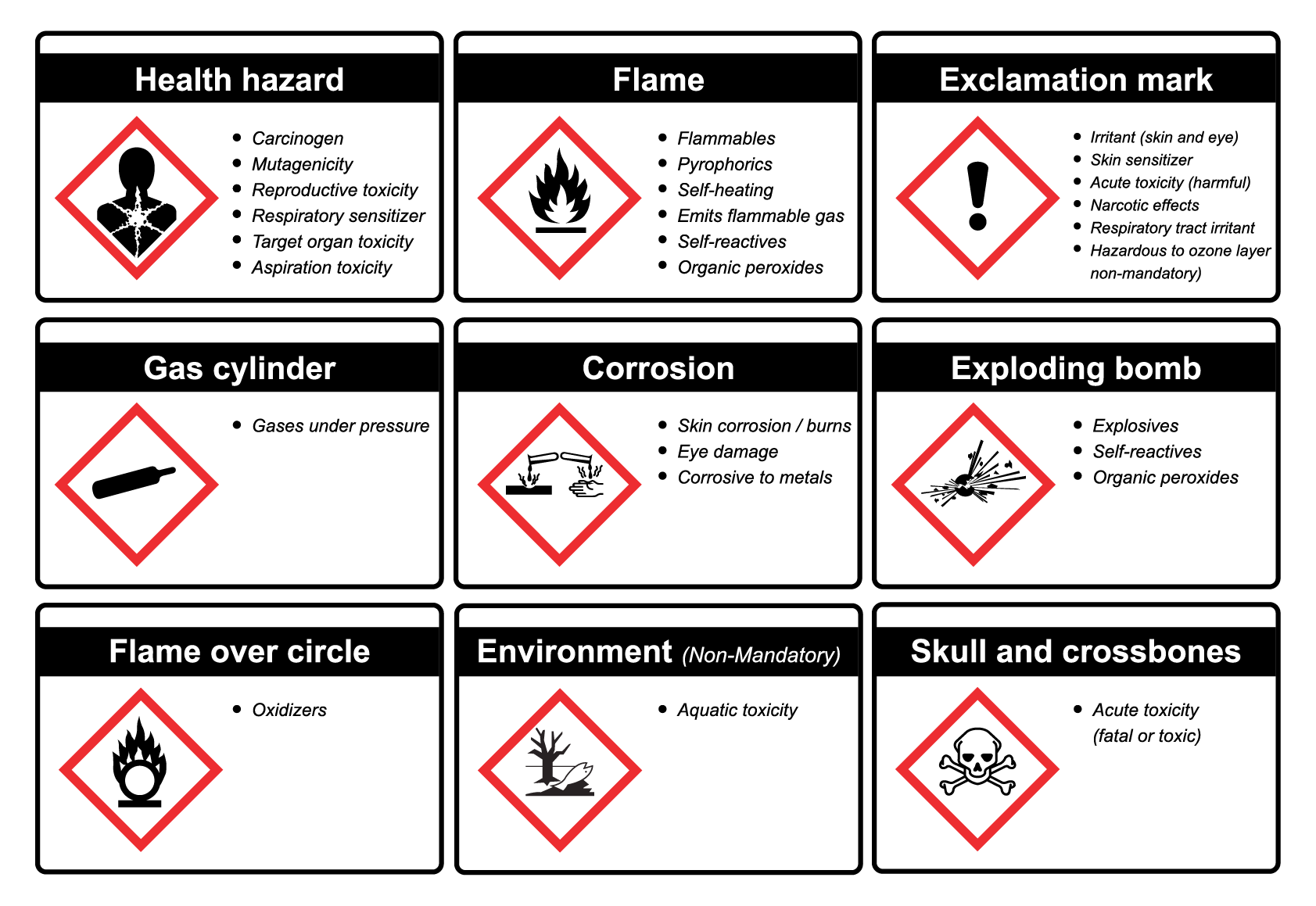

GHS labels display one or more of nine universal pictograms to help workers identify a chemical’s hazards. Labels must also show a signal word, either “DANGER” or “WARNING,” indicating the relative severity of the hazard. “DANGER” indicates a more immediate or extreme hazard than “WARNING” does.

GHS labels must include a hazard statement, which describes the nature of the chemical, and a precautionary statement, which describes the recommended precautions to minimize the effects of exposure to that chemical.

The label must also have a product identifier, which tells the chemical identity of the substance. Finally, GHS labels must list the supplier’s information, including the company’s name, address and telephone number.

GHS Pictograms

Each GHS pictogram is a black image on a white background surrounded by a red diamond:

Safety Data Sheets

Almost every chemical at your workplace should arrive with a safety data sheet (SDS), which contains information about chemical hazards, handling, storage and disposal information. SDSs will also contain exposure limits such as threshold limit values, permissible exposure limits and any other exposure limits recommended by the chemical manufacturer or importer.

An SDS must be available for each hazardous chemical in your workplace, and SDSs must be kept in a location where workers can access them as needed. If an SDS is lost or didn’t arrive at your facility with the chemical, you will need to contact the chemical’s manufacturer, importer or supplier to obtain additional copies.

All SDSs are required to be presented in a consistent 16-section format. The sections of a chemical’s SDS include:

- Section 1: Identification (product identifier, manufacturer/distributor name, contact info, recommended usage and restrictions)

- Section 2: Hazard identification (chemical classification under the HAZCOM standard, signal word, hazard statements, symbols, precautionary statements and any additional hazards)

- Section 3: Chemical composition

- Section 4: First aid measures

- Section 5: Fire-fighting measures

- Section 6: Accidental release measures

- Section 7: Handling and storage instructions

- Section 8: Exposure limits and protective controls

- Section 9: Physical and chemical properties

- Section 10: Stability and reactivity

- Section 11: Toxicological information

- Section 12: Ecological information

- Section 13: Disposal considerations

- Section 14: Transport information

- Section 15: Regulatory information

- Section 16: Other information (such as the date the SDS was prepared and/or last modified)

SDSs should be reviewed by each person that might handle, store or dispose of the chemical. Keep in mind that one SDS may apply to multiple, complex mixtures having similar contents and hazards.

SDS Hazard Rating

Each chemical’s SDS contains one or more hazard ratings, which are numbers or letters indicating the type or severity of the hazard. For example, flammable liquids are categorized from one to four, with one being the most flammable and four the least flammable. Self-reactives and organic peroxides are categorized by type – A through G – with A being the least stable and G the most stable. Acute toxicity is categorized from one to five, with one being most acutely toxic and five being relatively low acute toxicity.

The hazard category does not appear on the label; you can only find it by consulting the SDS. The label will show the correct pictogram, signal words and other hazard information appropriate to the chemical’s hazard category or type.

Non-GHS Sources of Information

While the Globally Harmonized System is the most common hazard information and labeling system you are likely to see in your workplace, you may also see other systems that do not align with the GHS system.

The National Fire Protection Association (NFPA) 704 system is an industry consensus standard used to indicate hazard type and magnitude to first responders. NFPA labels normally appear on buildings or storage tanks containing hazardous materials and are primarily used by firefighters and other first responders to quickly identify chemical hazards that could complicate an emergency. The NFPA’s numbered hazard ranking is the opposite of what is used in GHS. For example, ether, which has high volatility and ignites readily, is given a maximum fire hazard rating of four by the NFPA. However, ether is category zero under the GHS system.

Chemicals fall under the jurisdiction of the U.S. Department of Transportation (DOT) while being transported. Any hazardous chemical classified as a “hazardous material” by the DOT must have DOT pictograms and labels on the shipping container, as well as the OSHA container label information. However, OSHA pictograms should not repeat the same hazards as the DOT hazard labels.

Unlike GHS hazard ratings, the numbers on DOT labels and placards describe the type of hazard, not its severity. For example, bulk packaging for flammable liquids will always display the number 3, regardless of how flammable the liquid is. Check the chemical’s SDS to determine the severity of its hazards.

Conclusion

Chemical exposure can lead to a variety of illnesses and injuries, ranging from burns and rashes to nervous system damage, organ damage and cancer. However, having an effective HAZCOM plan in your workplace and training your workers over the plan can help keep them safe and healthy.

Introducing all employees to OSHA’s Hazard Communication (HAZCOM) standard and the methods for learning about chemical hazards is crucial for workplace safety, no matter your industry or your specific worksite.