The National Institute of Occupational Safety and Health (NIOSH) estimates that 61% of all oil and gas extraction workers are exposed to hazardous levels of noise. NIOSH also estimates that 19% of noise-exposed workers have trouble understanding speech, and an additional 8% of workers experience tinnitus.

Hearing loss occurs slowly over time, and workers may not realize they’re suffering hearing loss until it’s too late. It’s important for workers and employers to know what kinds of controls and hearing protectors they need to safeguard everyone’s hearing.

How Sound Works

In order to understand how our hearing can be damaged, we need to understand what sound is and how our ears work. Sound is created when objects produce waves of energy, called “sound waves.”

Sound waves enter our ears and stimulate small, delicate hair cells in the various canals and sections of the ear. These hair cells convert sound waves into nerve impulses, which our brains interpret as sounds. When these impulses are functioning properly, the human brain uses them to interpret up to 400,000 different sounds. Healthy hair cells stand upright and are responsive, but as they weaken, they lay down and become less responsive to sound waves, decreasing the level of sound the brain can hear.

The louder and longer a noise is, the more damage it does. Occasionally working around loud equipment can cause temporary hearing loss, but consistent or prolonged exposure to that noise could cause permanent damage. Tinnitus can also occur, which is a constant ringing or roaring sound in the ears. It happens when noise irritates hair cells to the point where they are constantly stimulated.

Noise on Oil and Gas Sites

Oil and gas workers are likely to encounter three main types of noise that contribute to the total noise exposure during their work shift, including:

- Continuous noise that continues indefinitely or stops for one second or less at a time. Continuous noise can come from machines such as generators, air compressors and engines.

- Intermittent noise that stops for longer than one second. Some examples include machines that are turned on and off intermittently, such as grinders and pumping units.

- Impulse or impact noises, which are single bursts of noise that can be extremely loud and dangerous. Some examples include using explosives for site prep or blowing down pipelines.

Hearing Conservation Regulations

The Occupational Safety and Health Administration (OSHA) requires employers to meet regulations designed to protect workers’ hearing. Most workplaces are subject to OSHA’s Hearing Conservation Standard, requiring employers to provide employees with hearing protection and noise monitoring if hazardous noise levels are present.

Some drilling and well-servicing operations are exempt from specific audiometric testing and noise monitoring requirements, but these operations must still implement protective measures or follow industry best practices to help protect workers’ hearing.

Hierarchy of Controls

To reduce the chances that employees could suffer hearing damage, work sites should use the hierarchy of hazard controls. Controls are tools or measures used to eliminate or reduce a hazard. From most to least effective, the hierarchy of controls is:

- Elimination and substitution — Removing noisy equipment altogether or using quieter equipment

- Engineering controls — Design changes to equipment, tools and work areas that remove or shield workers from noise hazards

- Administrative controls — Changes to work procedures and policies to reduce the duration, frequency and severity of noise exposure

- Personal protective equipment (PPE) — Hearing protection that reduces the amount of noise that enters workers’ ears and protects hair cells inside ears

Personal Hearing Protection

Most employees that require hearing protection will either use ear plugs or earmuffs. Ear plugs come in a wide variety of styles and levels of hearing protection. The specific ear plugs available can vary, but general categories include disposable ear plugs, reusable ear plugs, custom-molded ear plugs and ear canal caps. Earmuffs look like headphones but are for keeping noise out rather than pumping sound in.

Employers and employees should pick hearing protectors based on how comfortable it is for the wearers and the protection it provides from specific noise hazards on a given oil and gas site. In some cases, employees may require both ear plugs and earmuffs. Whatever hearing protection employees choose needs to provide enough protection while also properly and comfortably fitting with any other required PPE.

Noise Monitoring

Worksites with sustained average noise exposures of 85 decibels may need to perform noise monitoring, conducted by a competent professional. Noise monitoring can be done by sampling in a work area, personal sampling on and around an individual, or both. Area sampling is used for employees who stay in one area to perform their job, while personal sampling is used when employees must move from place to place to perform work duties.

There are two types of meters that measure sound: the sound level meter and the noise dosimeter. Sound level meters measure noise only when it happens, while noise dosimeters measure sound throughout the workday to calculate the average level of noise an individual is exposed to. Noise dosimeters are small and can easily be attached to employees’ clothes.

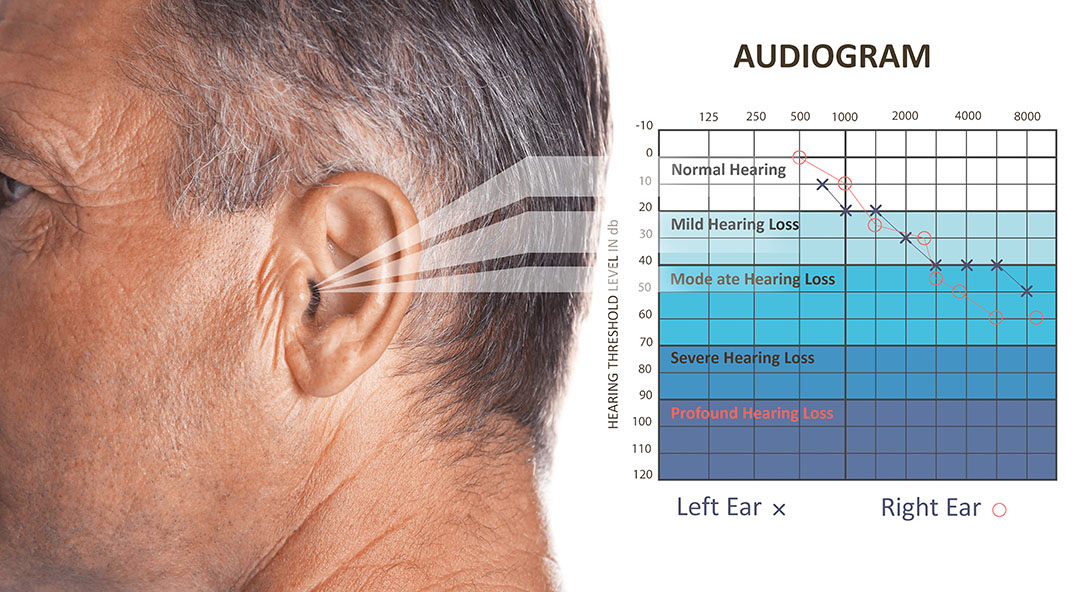

Your company may also be required to perform audiograms to determine workers’ abilities to hear sounds at different levels or pitches. Employees who are assigned to work in hazardous noise areas should have an audiogram performed when they first begin work and once every year afterward to track changes in their hearing. If employees are exposed to hazardous noise levels at any point after they are hired, they should receive an audiogram within six months of their first exposure.

Conclusion

Employees on oil and gas sites are subject to a wide variety of hazards but hearing loss might not be the first one that comes to mind. If employees are aware of noise hazards on their jobsite, they will have an easier time protecting their hearing so they can hear what they want to hear when not at work.

SafetySkills offers a Hearing Conservation training course specifically for oil and gas personnel that can help employees understand and protect themselves against the noise hazards on their sites.