Work Zone Safety Hazards

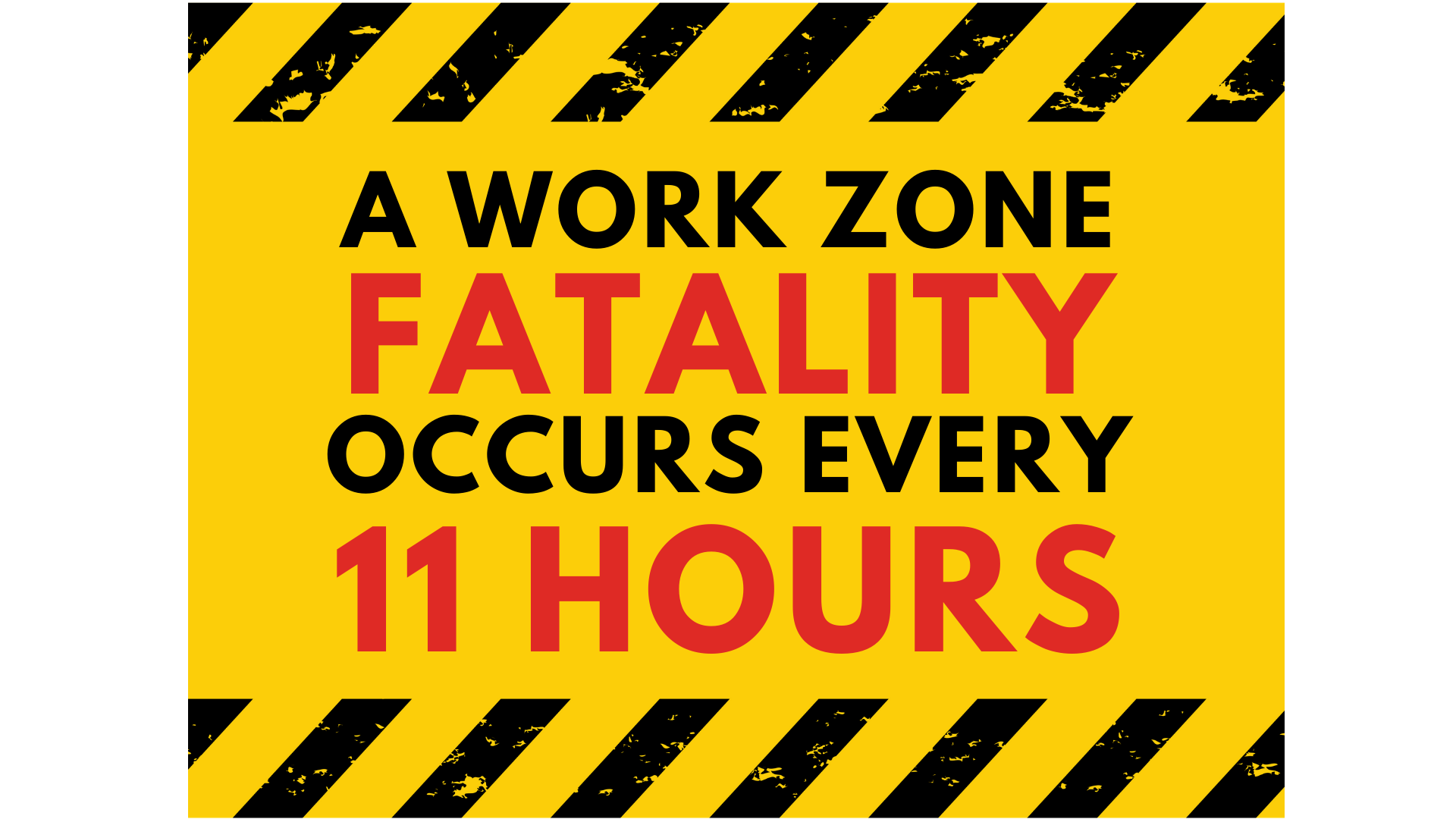

According to the Federal Highway Administration, there is a work zone injury every 13 minutes and a work zone fatality every 11 hours. Being prepared for what you and your employees might experience on a work site is an important part of keeping everyone safe. While it is your responsibility to ensure there are proper warning signs, drivers can be still be unaware, distracted or impaired, which means it is important to set up an escape path for workers in case of a dangerous or unaware driver.

All outdoor work comes with its own set of seasonal hazards. During the warmer months, workers could experience various forms of heat stress, the worst being heat stroke. To prevent heat stress, it is important to provide plenty of water and give your employees the chance to take breaks indoors, or at least in the shade. Try to schedule the more strenuous work in the cooler hours of the day.

Outdoor work in the winter can lead to cold-related illnesses, such as frostbite or hypothermia. To help prevent cold-related stress in your employees, remind them to wear multiple layers and drink warm, sweetened drinks to stay hydrated.

Nature hazards, such as animals or poisonous plants, are another concern. If an animal does come into the work zone, do not attempt to take custody of the animal, even if it looks domesticated. You should call animal control and have everyone maintain a safe distance until the animal is picked up or leaves the worksite. You should also train your employees on identifying poisonous plants, such as poison ivy, poison oak and poison sumac.

Flagging Operations

Flaggers have more contact with the public than anyone else at the worksite, which is why they should be trained in both safe traffic control practices and public communication techniques. You should also train your flaggers in how to:

- Recognize dangerous traffic situations

- Properly use traffic-signaling devices

- Apply safe traffic control practices

Certain states require more specific training or have certification requirements, so be sure to check your state requirements before clearing an employee for flagging duties.

It is your responsibility to place a “Flagger Ahead” sign an appropriate distance from the flagging station to give motorists plenty of time to react. Place the first warning sign at a distance four-to-eight times (in feet) the speed limit (in miles per hour). Use a higher multiplier for higher speed roads. For example, a 15-mph road should have its first warning sign at least 60 (15 times 4) feet from the work zone while a 65-mph highway should have its first sign about 520 (65 times 8) feet from the work zone.

Visibility is important for everyone in the work zone, but because flaggers direct traffic and are generally in the most exposed positions, it is critically important they wear approved high-visibility clothing. You should provide your flaggers with orange-red or yellow-red clothing with orange, yellow, white, silver or yellow-green retroreflective material that make them visible for at least 1,000 feet. All clothing should meet the American National Standards Institute standards for class 2 or 3 risk exposure.

It is always recommended that flaggers wear head protection to protect against flying debris but it in fact might be required by state law. You should also give your flaggers a whistle or horn so they can quickly let their co-workers know about emergencies.

The term “flagger” is slightly misleading because a STOP/SLOW paddle, rather than an actual flag, is the proper tool to provide to these workers. In emergency situations, such as a motor vehicle accident, a broken utility line or flooding, a STOP/SLOW paddle might not be available. In this case, flaggers can use a 24-inch by 24-inch red flag but should switch to a STOP/SLOW paddle as soon as it becomes available.

Ready to start your online safety training program?

GET STARTED WITH YOUR FREE TRIAL!

Positive Protection Devices

Positive protection devices are barriers that stop vehicles from coming into the work zone by either containing or redirecting the traffic. The primary purpose of the devices is protection for workers, while directing traffic is a secondary purpose. All devices should be inspected and approved by the Federal Highway Administration before use. There are five main types of devices. Each type has different advantages, briefly outlined below, and different deflection distances, or the distance they will move when struck.

- Portable concrete barriers

- Held down by their own weight

- Can be anchored to reduce deflection

- Used in long-lasting, heavy traffic work zones

- Unanchored deflection is up to six feet

- Anchored deflection is as little as one foot

- Ballast-filled barriers

- Filled with either water (for short-term work zones) or sand (for long-term work zones)

- Light and easy to move

- Higher deflection, so should only be used in low speed or low traffic areas

- Steel barriers

- Easy to install and transport

- Used in short-term work zones

- Unanchored deflection is six to eight feet

- Anchored deflection is nearly zero

- Shadow vehicles

- Used for short-term or mobile work zones

- Equipped with arrow panels or changeable message signs

- Follows workers as they perform tasks

- Vehicle arresting systems

- Portable netting and cables

- Prevent vehicles from entering work zones

- Help vehicles that do enter work zones to slow down safely

Pedestrian Safety in Work Zones

Sometimes work zones can be next to or in the middle of a pedestrian path. In this case, all pedestrians need to be accommodated, including pedestrians with disabilities. The accommodation will vary based on the type of work being done, the duration of the work and the hazards within the work zone.

Even for small, one-day work zones, accommodations must be made, even if it is just having an employee positioned at the edge of the work zone to assist pedestrians safely around the area. For long-term work zones or for work zones that will not always have workers present, more in-depth accommodations need to be put into place.

There are three main pedestrian-affected work zones:

- Working near a sidewalk where the sidewalk remains open

- Blocking a portion of the sidewalk

- Closing the sidewalk

If you are working near an open sidewalk, you need to identify and minimize the risks to pedestrians. Protection must be detectable by pedestrians with a vision impairment. If there are hazards that require protection, such as trenches, holes or falling debris within the workspace, it is even more important to prevent pedestrians from entering or walking across the work area.

If your work is going to block a portion of a sidewalk for an extended period, a temporary path should be made around the blockage. This path should be detectable to pedestrians with vision impairment and be wide enough for wheelchairs to pass through.

If you must close the sidewalk completely, a detour route should be established, and signs should be direct pedestrians to the detour path. All detour path signs should be detectable to all pedestrians.

Conclusion

Work zones are inherently dangerous, to both workers and drivers or pedestrians or enter a work zone. However, there are many preventive steps that can be taken to help minimize injuries and fatalities in these high-risk areas. SafetySkills offers a Work Zone and Flagger Safety course to help workers recognize work zone hazards and identify appropriate safety measures.