Electricity is used in a wide variety of laboratory equipment, ranging from specialized equipment such as autoclaves and centrifuges to everyday devices such as computers or light fixtures. Each of these items can present an electrical hazard to employees if damaged or used incorrectly.

Faulty equipment, overloaded circuits and other hazardous electrical conditions can cause severe injuries, so it is important that all lab employees understand the hazards of electricity in their work locations and how to protect themselves.

Hazards of Electricity

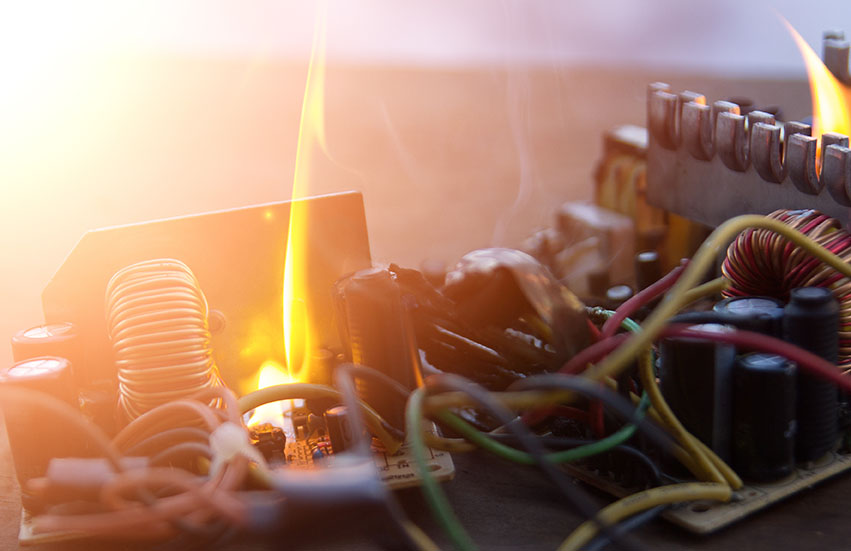

A short circuit is a fault where electricity flows outside the circuit with very little resistance. When a short circuit occurs, the low resistance allows more energy to flow through the system than intended. This can damage electronics and generate a lot of heat rapidly, which can melt wires and ignite flammable or explosive materials.

A ground fault is when the energy flows outside of the circuit back to the ground. If a ground fault occurs, it can energize an unintended part of the equipment, presenting a shock risk to anyone who touches it.

Shocks range in severity, from barely noticeable to instantly deadly. The severity of a shock depends on three main factors:

- Path the current takes through your body

- Amount of current flowing through your body

- Length of time your body is in contact with the current

While minor shocks may result in no injury, more significant shocks can produce a wide range of direct injuries including cardiac arrest, burns, tissue damage or even death. Severe injury or death by electric shock is known as electrocution.

Most electrical faults are also capable of producing sparks or arcs. Tiny, brief arc flashes are called sparks, but sustained arc flashes with more energy can be incredibly powerful. In some labs, arcs are created intentionally for certain applications. Both an intentional arc and an accidental arc flash, called an arc fault, can present arc flash hazards, including shock and burn hazards, explosion hazards, and hazardous amounts of UV radiation.

Arc flashes and electric shocks can also throw employees backward, causing indirect injuries such as sprains, fractures or lacerations. Any tool an employee is holding when they are thrown backward could fall too, potentially injuring anyone working or walking nearby.

Looking for more online safety training content?

VIEW THE 800+ COURSES AVAILABLE!

Electricity in the Lab

Standard electrical circuits found in houses and offices are designed to carry 120 volts, and the wires will be rated to carry a maximum flow rate of either 15 or 20 amps. In labs, however, major pieces of equipment often require a 200-volt or 240-volt circuit designed to deliver 20, 30 or 50 amps of flow. The outlets and plugs of these heavy-duty devices are designed to prevent employees from accidentally plugging a device into the wrong outlet.

You or your employees should never alter a plug to fit into a different outlet, as this could cause a dangerous overload, putting everyone in the lab at risk. If an outlet, piece of equipment or circuit needs to be rewired, hire a qualified electrician. Never attempt to rewire something yourself.

If your lab has a lot of equipment and not many outlets, it may be necessary to use extension cords and power strips. Both are safe when used correctly, but they come with their own sets of hazards.

Extension cords must be rated to carry sufficient amperage for the device, or it may overheat, damaging the equipment and putting employees at risk. Extension cords are also vulnerable to wear and tear from regular use, especially if they are improperly placed where they can become trip or snag risks. Cords can easily be pulled loose or damaged, leading to faulty connections, exposed wires and short circuits.

Power strips create additional outlets on an existing circuit, which is helpful if you have many low-amp devices in one area of your lab. While convenient, it is easy to plug too many devices into one circuit. Similarly, plugging multiple extension cords or power strips into one another, known as “daisy chaining,” increases the distance the energy must travel. This raises the resistance in the system, which in turn raises heat, intensifying the risk of overheating.

Many labs have at least one uninterrupted power supply (UPS) to ensure sensitive and critical equipment does not lose power during blackouts or other service interruptions. Because they are always on even if the power is suddenly interrupted, the UPS may still be drawing power during a fault event, presenting shock hazards. Usually, UPS devices will have built-in safety features to help prevent shocks, but you should still train your employees on where UPSs are located, how to operate them and any potential hazards they could present.

If your lab contains equipment that carries high voltages or the potential for arc flash hazards, such as electrical service panels or capacitor banks, this equipment should either be guarded to prevent hazards during normal operation or be isolated to an area for trained and authorized personnel only. The biggest risk to your lab workers comes from opening or tampering with electrical guards and covers or making unauthorized entry into hazardous areas. If a qualified electrician is performing maintenance work, they will most likely place temporary barriers and warning signs around the equipment.

Make sure your employees know to obey all warning signs and safety barriers in the lab, even those placed by outside contractors, and that they must always follow any safety instructions from electricians or maintenance technicians.

Employer Responsibilities

As the employer, it is your responsibility to evaluate the lab for hazards, develop a documented safety program, and ensure that appropriate safety signage is displayed around the facility. In order to protect your employees, you need to establish appropriate procedures and safety plans for when maintenance is happening on lab equipment. You are also responsible for ensuring all involved employees are properly trained over their roles and responsibilities during such procedures.

SafetySkills offers an Electrical Safety course specifically for laboratories to help employers and employees identify the potential dangers associated with electricity in a lab setting and understand how to manage and respond to such electrical hazards.